Cogeneration in detail

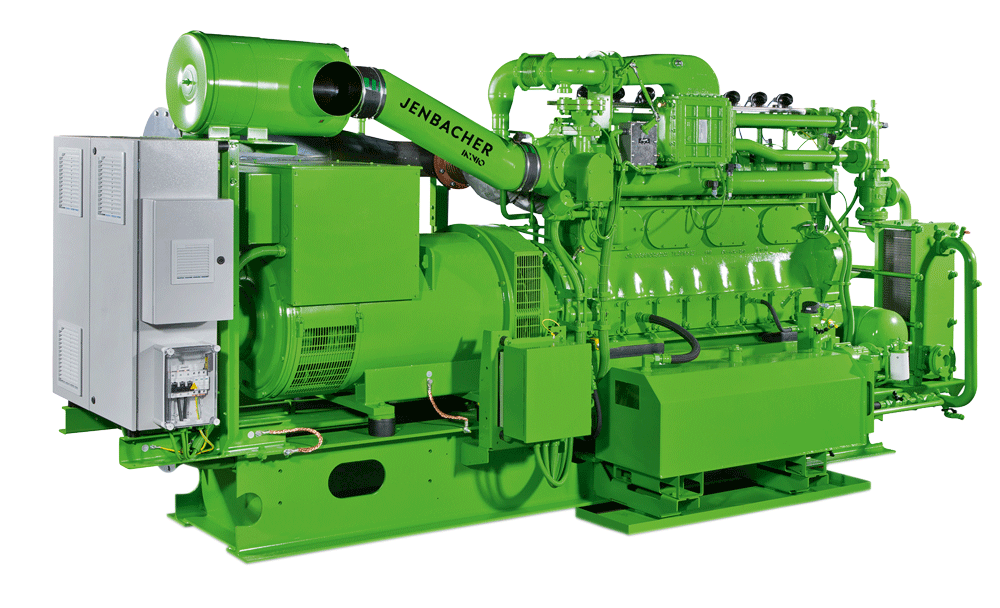

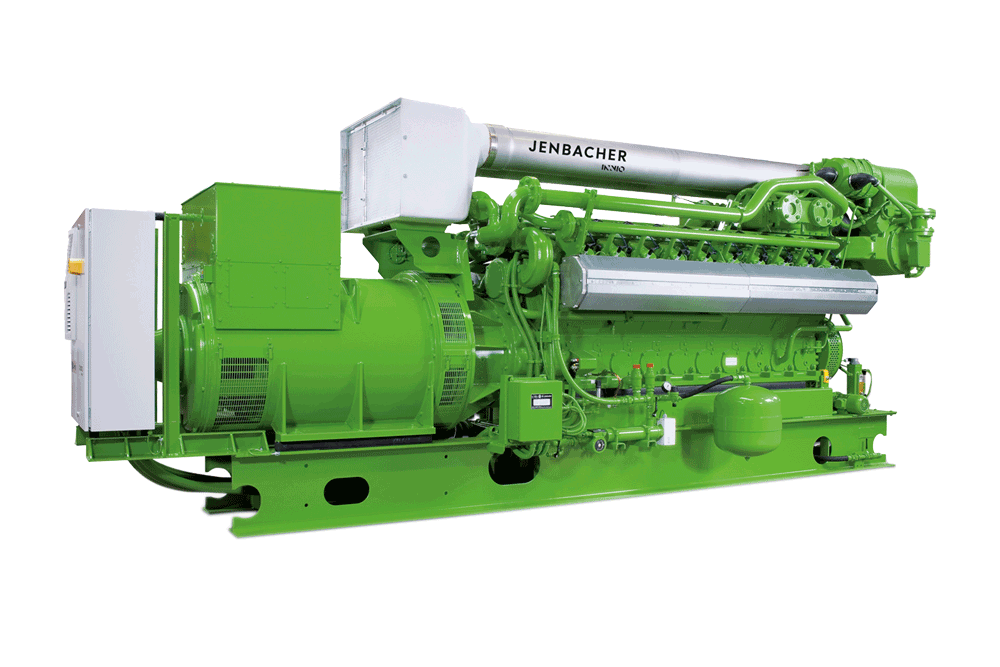

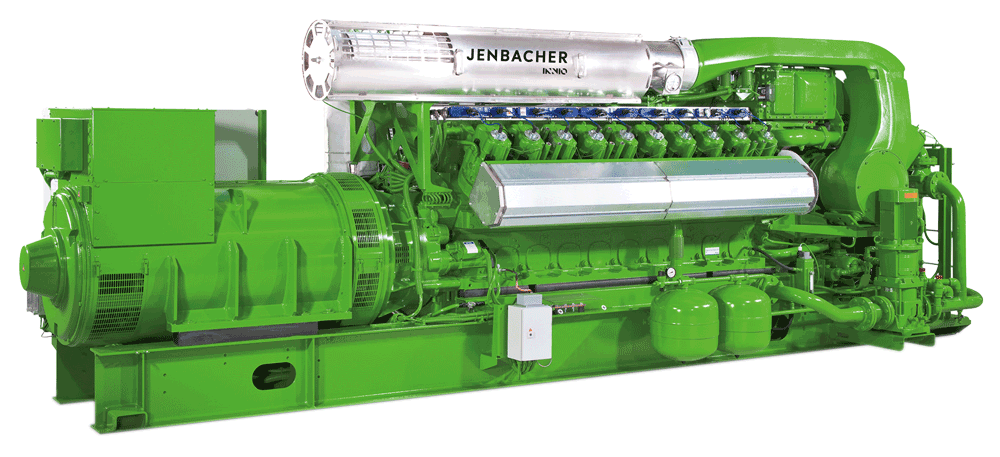

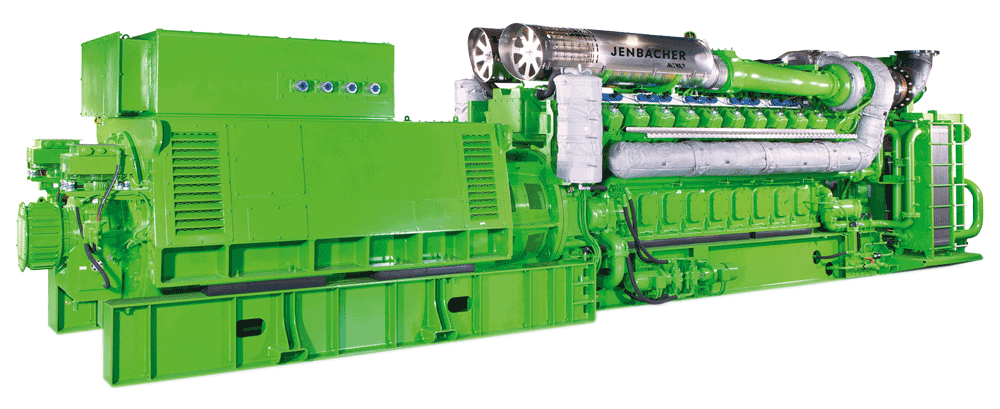

A combined heat and power (CHP) or cogeneration produces electricity (power) and at the same time heat. With a CHP-module the mechanical energy from for example an internal combustion engine or a gas turbine, is used to power a generator. This generator produces the electricity. The heat released during this process by the engine is recovered in the form of hot water, steam or hot air and is supplied as useful heat to the production process of the plant. Electricity and heat is no longer produced separately, which lowers your total primary energy demand and energy cost for the company.

With a CHP-system you not only produce electricity and heat in a combined way, but you also save on your energy expenditures and you reduce your CO2-emissions. Compared to a conventional power plant where the heat of the electricity production process is immediately lost to the environment in big cooling systems, a CHP-module uses this heat for useful applications such as heating, drying, ...

In addition to traditional natural gas engines Ecogen also has many years of experience with biogas projects. Agricultural companies or large companies with a lot of waste, convert their waste flows via a digestion plant into biogas, and with our CHP technology into electricity and heat. The waste residue that remains after digestion can be dried with the heat of the biogas engine to become a fertilizer or a soil improver.

Schematic presentation

100 units fuel

Cogeneration

A CHP (module gas engine) has an electrical efficiency of 40% and a thermal efficiency of 45%. This results in the following effective units

40 units electricity

45 units heat

Seperate generation

Power plant

A power plant has an efficiency of 50%. In order to obtain the actual return of 40 units of electricity, it needs 80 units of fuel.

Stookketel

A boiler has an efficiency of 90%. In order to obtain the actual return of 45 units of heat, it needs 50 units of fuel.

130 units fuel

Conclusion

Energy savings: 130 (80+50) - 100 = 30 units

Relative energy savings: 30/130 = 23%